Please Note: CFW visually inspects each spool after it is sealed in its packaging prior to shipping. CFW is not responsible for damage due to mishandling after the material leaves the CFW Facility.

Spool Receiving Inspection:

- As soon as possible upon receipt and before removing the packaging, examine the wire through the clear container to see if any spooling problems occurred during shipping (e.g. damage, loose strands, multiple ends, wire shifting, etc.). If damage is observed, do not remove spool from packaging or break the tamper-resistant seals – contact the CFW Sales Representative for a return material authorization number (RMA). Once the package has been opened and the tamper-resistant tags are removed, CFW can no longer control the quality of the product and cannot guarantee a credit or replacement.

- Per the T&Cs (http://www.calfinewire.com/faqs-return-policy.html), ensure that any shortages are reported within five (5) days and any other non-conformances are reported within thirty (30) days of arrival – otherwise material shall be deemed conforming.

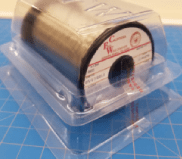

Standard Labeling for Each Spool:

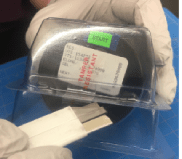

- Each spool of material will have a PSI sticker attached with these physical properties displayed: RES (Resistance as required), UTS (Ultimate Tensile Strength), YTS (Yield Tensile Strength), GBL (Grams Breaking Load), ELONG% (Elongation), HEAT (CFW Heat Number), and Barcode Number.

- Each spool will have a CFW “donut label” attached affixed to it with the following information displayed: Size, Date, Inspection #s, CFW Heat Number, Resistance, MO#, Tare Weight, Net Quantity, Material Description, Customer Part number (when required), and Purchase Order Number.

- Each spool of material is secured with a green “Start” sticker to secure the wire-starting end. Please note that once the Start sticker is removed, the wire will no longer be properly secured and may shift and become entangled and/or under-wound on the spool. To prevent this, maintain tension and/or re-tape the wire end after use and return to anti-static packaging for proper storage.

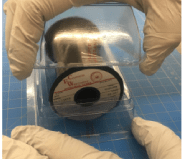

Safely Removing the Spool from Sealed Packaging:

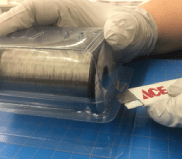

- The following equipment is required for properly and safely removing the spool from sealed packaging: box cutter / razor / cutting device and a level surface. Exam gloves are also recommended.

- The following instructions apply to all wire that is spooled onto a CFW-103 (see Table 001) spool and packaged into clear rigid PVC film containers.

- Set the sealed spool package onto a flat surface.

- Carefully cut the tamper-resistant seals on the bottom edges using box cutter / razor. This may also be done with the package held at a slight angle, but do avoid holding it in the vertical position.

- Secure the bottom flange / edge of the container to the flat surface with your fingers.

- With your non-anchored hand, use your thumb and forefinger to gently lift the top flanges / lid up and off the bottom half of the packaging.

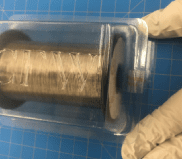

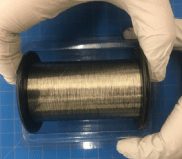

- Remove the now-accessible spool by grasping only the top and bottom flange ends as shown in Table 001.

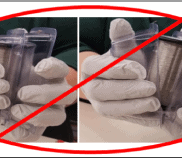

NOTE: Do not attempt to open this packaging vertically by pulling the two sides in opposing directions mid-air as shown in Fig-011 – the spool, while compression fit, could fly out under the force – always anchor the packaging to a flat surface when opening.

IMPORTANT: Never touch the wire. Touching the wire will cause breakage, kinks, fingerprints, or other damage (see Table 002). CFW is not responsible for damage due to mishandling after the material leaves the CFW Facility.