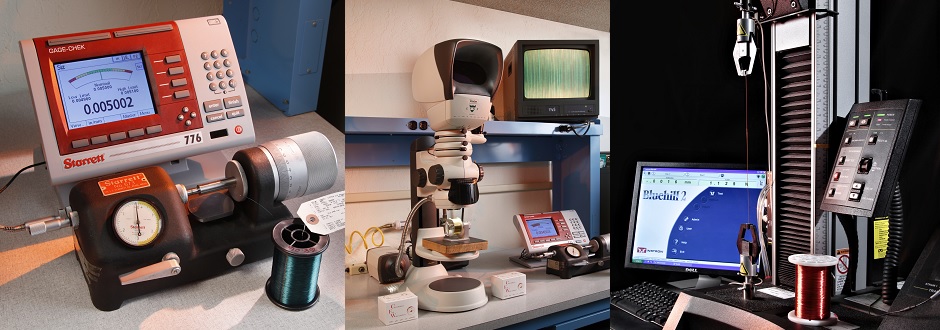

At California Fine Wire Co., we produce custom premium quality round and flat wire that is manufactured and tested to customer specifications. In-house testing is performed in accordance with our ISO 9001 certified quality management system. Testing capabilities include dimensional inspection, tensile testing, and measurement of the electrical resistance in the wire. Dimensional inspection equipment is capable of measuring wire with a resolution of 0.00001″ and an accuracy of ±0.00005″. For applications that require the highest degree of precision, we can provide an ultra finish using diamond dies, that results in the tightest dimensional tolerances and smoothest surface finish available.

Tensile testing can be performed to verify the strength of wire when load bearing capacity is a concern. Our tensile testing equipment measures the tensile strength of wire to within ±1% and individual lots of wire can be labeled with the measured tensile strength upon request. For wire that is to be used in electrical applications, we can measure the resistance of the wire with an accuracy of 0.01%. The materials we use can be sourced to meet DFARS, REACH, and RoHS regulations as needed and our company is ITAR registered to ensure that we comply with all regulatory requirements of the aerospace and defense industries.

In addition to quality testing, our team can accommodate a range of special handling needs from ultrasonic cleaning to custom packaging for any range of production volume. For additional information about our comprehensive wire quality testing capabilities see the table below, or contact us directly.

Testing Specifications

- Testing Capabilities

-

Dimensional Inspection

Tensile Testing

Resistance Measurement

- Testing Accuracy

-

Dimensional Inspection: ±0.00005″

Tensile Testing: ± 1%

Resistance Measurement: 0.01%

- Testing Resolution

-

Dimensional Inspection: 0.00001″

Resistance Measurement: 0.0001″

- Wire Configurations

-

Round

RibbonDuplex

Stranded

- Wire Materials

-

Aluminum

Copper

Nickel

Nickel Alloys

Resistance Wire Alloys

Thermocouple Alloys

GoldSilver

Platinum

Platinum Alloys

Glass Sealing Alloys

Bonding Wire

Numerous Additional Options Available

- Finish

-

Bare

Enamel

PTFECeramic

Plated

- Wire Length

-

Cut Lengths: 0.125″ to 72″

No limit on spooled lengths

- Wire Diameter

-

0.0004″ to 0.10″

10 microns to 2.5 mm

Other Sizes on Request

- Production Volume

-

Prototype

Low Volume

High Volume

- Typical Lead Time

-

Quoted on a Job by Job Basis

Additional Information

- Industry Focus

-

Aerospace

Defense

ElectronicsMedical

Research & Development

- Industry Standards

-

ISO 9001 Certified

DFARSREACH

RoHS