Please Note: CFW visually inspects each spool after it is sealed in its packaging prior to shipping. CFW is not responsible for damage due to mishandling after the material leaves the CFW Facility.

Inspecting Wire Prior to Handling:

- As soon as possible upon receipt and before removing the packaging, examine the wire through the clear container to see if any spooling problems occurred during shipping (e.g. damage, loose strands, multiple ends, wire shifting, etc.). If damage is observed, do not remove spool from packaging or break the tamper-resistant seals – contact the CFW Sales Representative for a return material authorization number (RMA). Once the package has been opened and the tamper-resistant tags are removed, CFW can no longer control the quality of the product and cannot guarantee a credit or replacement.

- Per the T&Cs (http://www.calfinewire.com/faqs-return-policy.html), ensure that any shortages are reported within five(5) days and any other non-conformances are reported within thirty (30) days of arrival – otherwise material shall be deemed conforming.

Standard Labeling for Each Spool:

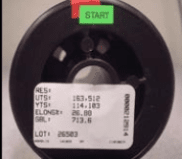

- Each spool of material will have a PSI sticker attached with these physical properties displayed: RES (Resistance as required), UTS (Ultimate Tensile Strength), YTS (Yield Tensile Strength), GBL (Grams Breaking Load), ELONG% (Elongation), HEAT (CFW Heat Number), and Barcode Number (see Figure 1).

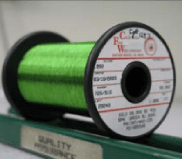

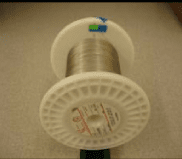

- Each spool will have a CFW “donut label” attached affixed to it with the following information displayed: Size, Date, Inspection #s, CFW Heat Number, Resistance, MO#, Tare Weight, Net Quantity, Material Description, Customer Part number (when required), and Purchase Order Number (see Figures 2, 3, and 4).

- Each spool of material is secured with a green “Start” sticker to secure the wire-starting end (see Figures 1, 3, and 4).Please note that once the Start sticker is removed, the wire will no longer be properly secured and may shift and become entangled and/or under-wound on the spool. To prevent this, maintain tension and/or re-tape the wire end after use.

Opening the CFW Box, if applicable:

- Carefully remove the spooled material within the plastic bag from the packaged box by holding the bottom of the box and carefully pulling the top half of the plastic bag straight up and away, taking care to not let the edges of the box come in contact with the wire on the spool as this may cause breakage or kinks in the wire.

- If you notice wire damage during receiving-inspection, please notify CFW immediately so arrangements can be made to evaluate the wire for a potential replacement.

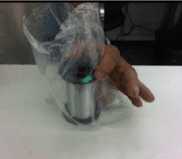

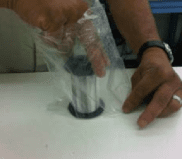

Removing the Spool from the Plastic Bag, if applicable (refer to images on reverse side):

- Place the spool on its flange onto a flat surface (see Step 1).

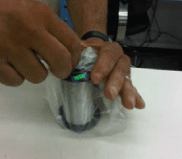

- Use one hand to stabilize the spool by the top flange while being careful not to touch the wire. Once stabilized, begin opening the plastic bag (see Step 2).

- While still maintaining stabilization, open the plastic bag fully making sure not to introduce any type of contact to the material itself (see Step 3).

- Use one hand to hold the plastic bag down to the flat surface. Use the other hand to carefully remove the spooled material from the plastic bag, once again being careful to not touch the wire (see Step 4).

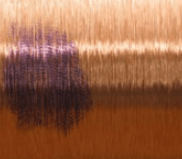

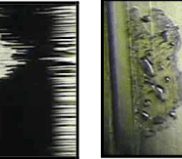

Please note: Touching the wire will cause breakage, kinks in the wire, and/or fingerprints (see Figures 5, 6, 7, and 8).

Mishandling:

Please note: CFW is not responsible for damage due to mishandling after the material has left the CFW facility. This includes improperly securing the starting end of the spooled material and allowing the single strands to become entangled with each other, fingerprints, scratches from surfaces (edges of counters or packaging), or from fingernails.

- The most common handling damage to the wire is an unsecured starting end. The starting wire end must be kept under tension when the start end is un-taped. If it is allowed to unravel or become loose on the spool, the wire will shift on the barrel and become underwound or tangled with other wire strands (see Figure 7). Securing the starting end at all times can prevent this as well as using a proper payoff.

- Fingerprints are another common form of mishandling damage. When a finger touches the wire, a combination of physical damage and residue is imparted onto the wire. The residue from the finger salts will oxidize the wire as shown in Figures 5 and 6.