California Fine Wire Co.’s quality management system is ISO 9001 certified and conforms to the latest benchmarks for quality systems.

Our laboratory and testing facility is available to perform most electrical, physical, metallographic, and chemical tests.

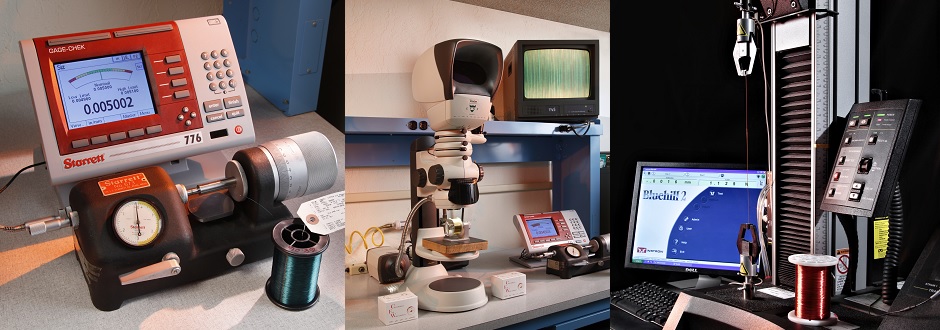

California Fine Wire maintains an extensive amount of testing equipment to ensure the highest quality products are manufactured and that they conform to customer and industry specifications. Testing is an integral component of the Quality Process at CFW and many tests are performed on your product at every stage of the production process.

Equipment is maintained at testing stations in each production department and in Quality Assurance. Calibration checks on many pieces of equipment are performed daily. Equipment calibrations are performed on a scheduled basis by CFW or outside contractors according to ANSI and other standards. When required, standards traceable to NBS are used. CFW can perform most physical, electrical, and metallographic tests that are required. For a detailed list of tests provided, please refer to the List of Tests in Related Links.

Examples of test equipment accuracy:

- Dimensional Measurement: resolution = 0.00001″; accuracy = +/- 0.00005″

- Tensile Testing: accuracy = +/- 1%, repeatability = 1%

- Resistance Measurement: resolution = 0.0001 Ω; accuracy = 0.01%

Customized test reports can be prepared that provide specific detailed information requested by the customer. For example, if a customer was interested in the detail of tensile test results, we could provide the results for each sample, including the stress-strain curves. This could even be provided for different stages of processing. Providing SPC data for dimensions would be another example. Please click one of the logos below to see our ISO certification.

Quality Management System

is ISO 9001 Certified