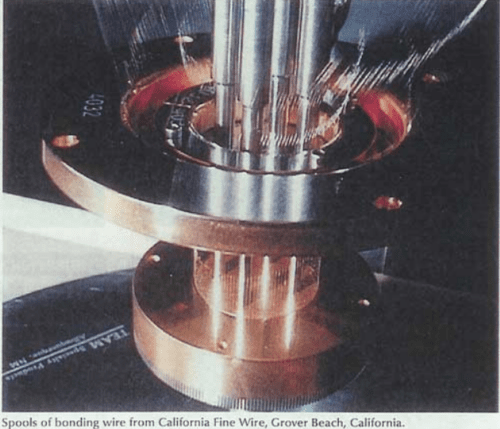

By Mike Greenelsh, President California Fine Wire Grover Beach, California

Specially shaped fine wire has been for many years. Applications range from everyday consumer products, such as toasters, to elegant medical equipment and high tech electronics. Naturally, the question arises: do you know as much about shaped fine wire as you thought you did?

Depending on your answer, you may be ready to consider whether a specially shaped fine wire might be good for your product. An excellent way to find out is to test your knowledge of some of the basics about shaped fine wires and their applications. Following are answers to ten basic questions:

What do we mean by “shaped”fine wire?

“Basic” wire Is round, made from metal rods milled down to a final size by rod mill rollers.Shaped wire is reformed Wire, often cold drawn through a metal die or “Turks head” type rolling mill to change its shape and size.Typical forms for shaped wire include: square, with radius “corners;” square, with square cut radius Corners; oval:hexagon;octazon;ribbon and triangular shaped wire.

For shaping purposes,what range of dimensions qualify as “fine” wire?

The fineness of fine wire ts driven by new applications. Today’s shaped fine wires can be as slender as 0.00030+0),.000025 inch. Thats less than one tenth the thickness of the typical human hair. At the other end of the spectrum, a thickness of 0.002 in.would be considered the upper limit of fine wire. For example, 0.0012 inch diameter gold wire can be rolled to 0.00025 thick by 0.005 wide, ribbon.

Can you name 10 common applications for shaped fine wire?

The possibilities are virtually endless, but to name a few: guitar amp pickups, metal “keys” for aerospace vehicles, metal catheters, mini springs, connector pins, integrated circuits, microwave systems, power coils, audio speaker coils, microwave

Fine Wire

coaxial cable, and miniature railroad track. Some applications, such as heater elements for toasters, use flat wire ribbon to provide a broader, heat conductive surface. In addition to these commonplace uses, there are many highly specialized applications, such as cochlear hearing implants,heart probes, and telemetry devices.

Shaped wire is also used in some unusual applications, such as linear motor actuator coils for computer disk drives. For example, one customer of California Fine Wire required his wire to be,square in shape,with a special insulation of Pyre-ML enamel.

How many kinds of fine wire can be shaped?

In terms of sheer numbers, a surprising amount is available. At California Fine Wire (CFW), we offer 1,000 different metals and alloys, 90% of which can be drawn or rolled into shapes. This number is multiplied by the variety of different coatings available for use in strengthening or insulating the wire itself, For example, we can insulate shaped wire against extreme temperatures by using coating materials such as Alcal and Cereal, a glass/metal compound that is capable of operating within a temperature range of 368°F to 1300°F.

What is the minimum amount of shaped fine wire that you can order?

The answer to that question often surprises people: one linear foot! The reason is that we have to accommodate engineers who want to run tests or develop prototypes prior to a production run of a product.

More typically,however, there are customers who limit their orders to hundreds of feet at a time.These are usually the producers of limited production devices that require relatively small amounts of shaped wire. Keep in mind, though, that it may cost a hundred dollars to produce that minimum run. Considering the fact that the die that is used to shape the wire may typically cost $10,000 to make,the price for the minimum run becomes relatively reasonable.

What is the maximum amount that you can order from a typical supplier?

In many instances, producers of shaped fine wire will limit orders to a monthly or annual maximum volume.This policy may be the result of limited capacity or the need to avoid becoming “captive” by a few or even a single customer. In general, I would estimate the maximum volume to be in the neighborhood of five million feet per month.

What quality should you a in shaped fine wire?

Fine wire manufacturers can output consistent quality that is “Six Sigma.” Although the science of drawing wire has not been perfected, achieving the exact tolerances and specifications required by modern applications should not be a problem.

Is technical support required to spec a shaped fine wire?

If customers do not have the needed technical support in house, they should be able to rely on their supplier. The wire manufacturer should have engineers or other technicians available to provide design assistance.This is especially important early in the development process, when many potential pitfalls can be avoided. In fact, product design engineers often call on us looking for suggestions or ideas on material use, dimensional

concerns, and process questions. And we’re happy to provide the needed expertise.

How long does it take to make shaped fine wire?

Orders can be filled in five days or sooner. In some cases, manufacturers exceed customer orders and store the extra for fast turnaround of future orders. To provide the fastest turnaround, CFW inventories over 135,000 rolls of fine wire. However, it is a good idea to confirm that the shaped wire fabricator meets deadlines and responds quickly to orders.

Can shaped-wire suppliers provide secondary operations, as they do for regular round wire?

It is essential to confirm that the wire fabricator can provide all secondary operations, forming, coiling swaging, camfering, and heat treating. A customer should also confirm that the fabricator can provide such services as packaging, plating, installation of terminals,drilling, notching, abrasion tumbling, cut to length, soldering, brazing, and laser cutting.

Mike Greenelsh is President and founder of California Fine Wire, which can roll or draw wire made from over 1000 different metals and alloys, down to diameters as small as 0.0003 +0.000025 inch. For more from California Fine Wire products, circle RF133.