Pop quiz: what common,everyday material is used in both lunar modules and toasters? In astrophysical research and the dash of your car? To probe the innermost reaches of the human heart, and to power TV sets? The surprising answer is wire the strands which link the mundane with the extraordinary. Even more surprising is the diameter of the wiring being used in today’s exotic applications, as thin as one tenth of a human hair or smaller.These gossamer strands are expanding the boundaries of scientific research and are a vital component in many new hightech devices,

Micro thin wires composed of various alloys have virtually limitless applications, as their conductivity, strength and thickness can all be custom tailored for use in any conceivable environment. High resistance wire alloys can be used to generate heat or light, while superconductive alloys, offering nearly zero resistance, have allowed virtually instantaneous data transmission for today’s high speed super computers

The need to reduce weight, increase operating speeds, and minimize equipment size advanced the miniaturization of integrated circuits used in airplanes, submarines, and computers. As more functions have been crammed onto single semiconductor Chips, increasingly finer wires are required to efficiently transmit data produced by these components.

The art of producing such minute wire 18 is an exact science. Large diameter wire is drawn through a series of progressively smaller diamond dies and rewound onto spools.Each pass through a die further reduces the wire’s diameter and increases its length.

“The wire 1s actually being stretched to a smaller size,” explains California Fine Wire president Mike Greenelsh. “If we start with a ten foot wire that is .020 inches in diameter and draw it down to half its diameter, Say .010 inches, we create a wire that is four times its original length, or forty feet.”

Although the art of drawing wire is not new,achieving the exact tolerances and specification required by modem applications is a craft still being perfected. The wire quality and condition of the die is extremely important,considering that the finished wire can be one tenth the diameter of a human hair three ten thousandths of an inch.Even a microscopic burr in the die could produce an unacceptable scratch in the wire.

Fortunately, advances in ultrafine wire production techniques have stabilized quality and cost and have encouraged various industries to develop innovative uses for the wire. In the medical field, applications include electrical stimulation of injured muscles and surgical reattachment of lenses to the eyes of cataract patients. Heart and artery inspection and repair, previously possible only via traditional surgery, can now be performed safely without such drastic measures by using tiny instruments introduced into the patient’s arteries and guided by spider web thin high resistance wires. This practice greatly reduces patient discomfort and recovery time.

Extremely delicate wires are also being used in cochlear implants that restore hearing and speech; the wires bypass damaged parts of the inner ear and transmit minute electrical impulses directly to the hearing nerve and ultimately to the brain for processing. Other applications include tiny internal sensors used to measure pulse rate,body temperature, and even blood flow rates.

Fine wire also plays an integral part in studies of tissue damage (ischemia), due to heart attacks, being conducted at the University of North Carolina at Chapel Hill. During a heart attack, potassium and hydrogen ions migrate into the extracellular space of the blood deprived heart muscle. Fabricating probes that can be used to detect these ions, the lab starts with .005″ thick silver wire with a .002″ thick clear Teflon coating. They next cover the wires with a thin sponge layer and selectively permeable membranes in a meticulous process.

In these experiments, the probes are inserted into a pig’s heart using a hypodermic needle. The artery to the heart is then tied off, simulating a heart attack. The probes measure the ionic changes that occur in the heart muscle as a result of this “attack.” The quality of the wire used for the probes is critical; if the wire is too brittle it will break during probe fabrication. Cracks in the Teflon coating will minimize the probe’s effectiveness or prevent it from working at all, and if the coating is too thick the probe will be difficult to insert and could break.

By understanding the physiology of heart attacks it is hoped that interventions can be developed that will minimize resulting damage. “This is basic research,” said Research Analyst Connie Engle. “We’re just trying to learn how the heart works so we and other medical researchers can build on the knowledge we uncover here. We couldn’t do our current electrical or ionic tests without fine wire.”

The creative forces that continually fuel innovations in world industry have constantly challenged California Fine Wire (CFW), headquartered in Grover Beach, California.Since its founding in 1961, CFW has shipped fine wire worldwide for use in almost every industry and area of research.

When he founded CFW, President Mike Greenelsh dreamt of producing wire products that other companies considered impossible or were unwilling to attempt. “Basically, we started out to provide a product and service that wasn’t available in the industry aultrafine wire with very fast delivery. We are willing to work with the customer in producing wire to make prototypes of their products,” stated Greenelsh, “We often do simple engineering and make recommendation for materials that will help customers solve their problems.”

Over the years CFW has developed techniques that permit them to draw, anneal, and insulate over 950 different kinds of metals and alloys. In the process they have provided wire for many foreign countries and numerous research projects. For example, CFW worked with the energy research departments of universities to develop gold plated wire for sensors used in various experiments on the behavior of atoms and electromagnetic waves.

“Our wires are used in instruments that can sense collisions between atomic particles,” said Greenelsh. “These instruments can tell how fast the particles are going when they collide, how much energy was generated, and even the trajectory of the particles. With the aid of our wire connected to various pieces of equipment, scientists are even able to monitor cosmic rays that pass through our bodies and constantly bombard the world from outer space.”

CFW’s ultra fine wires can also be found at the heart of a massive, twenty million amp, accelerator in the pulse power research program at Sandia National Labs in Albuquerque, New Mexico. Their quest for higher and higher quality wire with precise dimensions and tolerances led Sandia to utilize CFW products in the energy research experiments they perform for the Unites States Department of Energy.

According to Sandia the diameter of the wire needs to be extremely consistent because it affects test results. In the past they had problem with wire that was so inconsistent that their test results and calculation were invalidated. Redoing these tests is very expensive. Thankfully,California Fine Wire has met every challenge that Sandia has given them.”

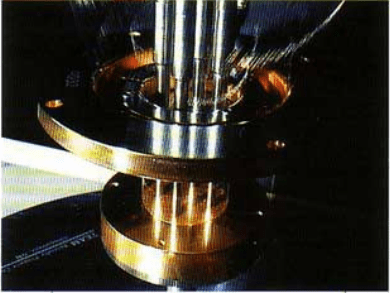

Sandia relies on CFW’s ultrafine wire in its Z Pulse Power

Accelerator,billed as “the world’s most efficient laboratory x-ray source.” In the very center of Z Accelerator is a circular wire array made of ultrafine Wires, The array is fashioned from two slotted rings, which may hold anywhere from 90 to 480 wires located precisely around their outer circumference. Each wire has a tiny copper weight placed on its end for tensioning. The finished array, which closely resembles a small birdcage, is then placed in the target region of the accelerator.

The Z Pulse Accelerator resembles a large bicycle wheel with the array located at its hub.A tremendous electric current (20 million amperes) is transmitted down the “spokes” of this wheel and focused on the array in a pulsed burst lasting less than ten one-billionths of a second, to instantly vaporize the wires and create ionized gas or plasma. Magnetic forces created around the array cause the plasma to implode, or “pinch,”producing a short intense burst of x-rays and initiating temperatures of at least 1.5 million degrees. Different materials used in the arrays such as aluminum,titanium, and tungsten in sizes ranging from 4 to 20 microns determine the spectrum of x-rays that will be generated.

Since the x-rays and temperatures resulting from this implosion are very similar to that produced on the surface of stars, it

can be used to help scientists understand space’s mysteries.For example, the radiation output from a pulsating star called the Cepheid Variable is now better understood because of data from 7-pinch implosion experiments.

The pulsed power research program at Sandia relies heavily on CFW’s willingness to invest time and effort into the kind of

research and product development that most companies are not capable of doing for themselves. Research and development is an integral part of CFW’s service; not only do they produce fine wire, but they have the ability to insulate or coat wire with almost any material including formvar, polyurethane, polyesters, polyimides, nylon, and various bonding coats. A new area of interest is ceramic insulated wires for high temperature applications (up to 1300 degrees Fahrenheit), a capacity they are developing in response to the needs of their customers.

California Fine Wire is working with Sandia to develop even finer wire for use in their experiments. For instance they’re currently working on developing an almost impossibly fine, 2.9 micron thick, titanium wire for use in one of their tests.

“Ultra fine wire is our product,” confirmed Greenelsh. “However, our real specialty is fulfilling our customer’s needs. We are really a raw materials manufacturer of very unusual products. We pride ourselves on our quality assurance program, and have added qualified personnel and updated our equipment whenever required. If a company has a difficult wire problem, we’ll try to solve it for them.”

CFW found its niche in the fine wire business because they were willing to provide small amounts of wire to customers who had trouble finding a company that would bother with them.

“We are willing to work with the customer in developing their products in small quantities,” stated Greenelsh. “Often times they will go to a wire company needing only a thousand feet of wire and that company will want to sell them a thousand pounds, We will produce ten feet if that’s what a customer wants!”

For more information:

California Fine Wire

P.O. Box 446

Grover Beach, CA 93493-0446

Phone (905) 499-5144

Fax (805) 499-5352

www.calfinewire.com