With more than 60 years of experience, California Fine Wire Company is an industry leader in the creation of customized precision wire solutions. In addition, we continually strive to provide our customers with unparalleled quality and customer support. Here are the metal wire products and services we offer.

Fine Wire Products

We offer the following custom fine wire products.

Drawn Wire

We utilize precision drawing dies to manufacture custom precision drawn wire that measures between 10 microns and 1 mm in diameter. Depending on the project specifications, we can either cut the wire to length or package it on spools. We also offer an “ultra finish” option, utilizing precision diamond dies to meet the tightest tolerances.

Insulated Wire

Our facilities house 25 enamel-coating machines, enabling us to take on custom insulation projects of any size. We offer a wide range of enamel-coating choices and can work with virtually any alloy wire, provided it has a diameter of between 25 microns and 0.5 mm.

PTFE Insulated Wire

For applications requiring non-stick or low friction properties, PTFE insulated wire is often the product of choice. PTFE has the advantage of being chemically inert in the majority of applications. Our PTFE wires have a single layer of coating, enabling them to meet very tight tolerances.

Electroplated Wire

Depending on the material used, electroplated wire can be corrosion resistant, conductive, and solderable. We electroplate using nickel, copper, silver, gold, tin, or tin-lead at varying thicknesses. Our experienced sales and chemist teams work closely with our customers to determine the most appropriate material options for the desired application.

Flat Ribbon Wire

Our flat ribbon wire is available in thicknesses ranging from 0.0002 inches to 0.05 inches, with widths ranging from 0.002 inches to 0.1 inches. As we provide custom services, we can often produce alternate wire sizes as well. We will generally utilize a flattening ratio of up to 40:1.

Stranded Wire

We offer custom-stranded wire products in a range of alloys, including copper and aluminum. These stranded wires are available with PTFE, ceramic, or polymer enamels. Generally, we will utilize wire between 25 microns and 2.5 mm in diameter, in strand configurations of either 7 or 19 strands.

Annealing

When high-strength properties are undesirable, the annealing process is an excellent option. By heating the wire, we are able to release any stresses within it and create a more homogenous product with better ductility. We provide annealing services for both small and large-volume projects. Upon request, we also offer vacuum annealing.

Wire Straightening

Typically, we will perform wire straightening in projects where the wire is cut to length. This wire is available in both small and large production runs. Wire straightening provides tighter tolerances and is ideal for applications in industries such as aerospace, defense, and medical.

Customer Service

Choosing the optimal design for a custom wire product can be challenging. At California Fine Wire Co., we use our decades of experience to help guide customers in selecting the products that best suit their needs for the desired application. Our customer service support covers everything from identifying the ideal types of wire and coatings to choosing between cut and spooled wire.

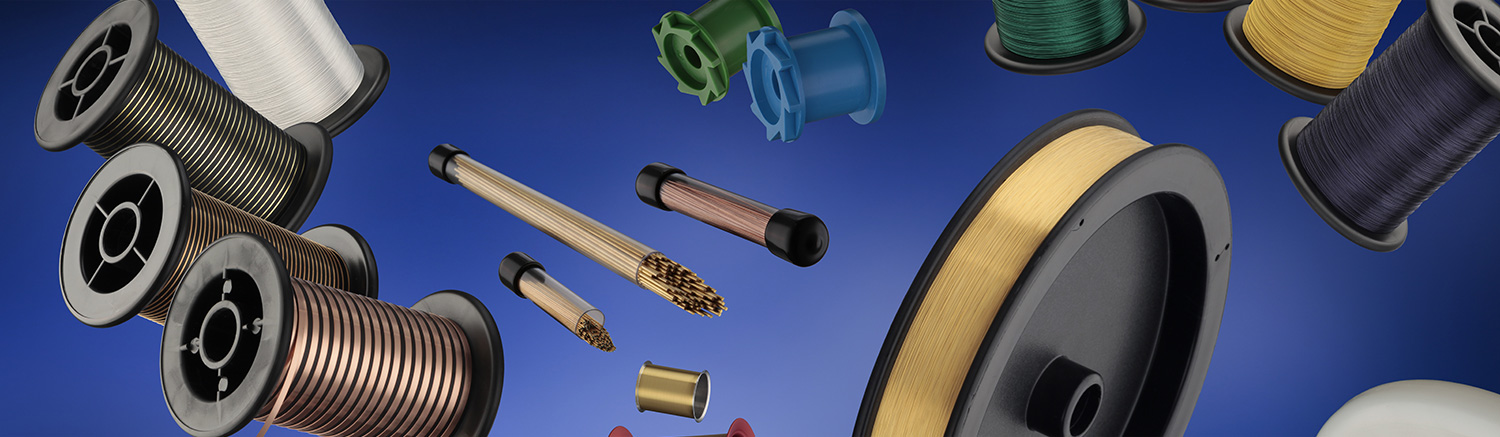

Packaging & Spooling

Prioritizing careful wire packaging ensures that our customers can properly utilize their precision wire products. Poorly-spooled wire reduces efficiency and may lead to wasted product. To avoid this, we offer a range of different spooling options, including metal, plastic, bonding, and braiding. Upon request, we also provide DIN spools and specialized jigs to accommodate unique projects.

Special Handling & Processing

Many of our customers require fine wire for unique, highly specialized applications. As such, we have years of experience meeting these needs. We provide customized processes such as chemical and ultrasonic cleaning, as well as multiple types of material testing. As we provide these services in-house, the use of a secondary vendor is unnecessary, and production is more efficient and affordable.

Fine Wire Testing

Our range of fine wire testing services include tensile testing and dimensional inspection. Our equipment provides an accuracy of ±0.00005 inches. Additionally, we will measure the electrical resistance of wire intended for use in electrical applications. We are ITAR registered, and meet DFARS, RoHS, and REACH standards.

Ultra Finish

By utilizing customized diamond dies, we can produce round wire that meets extremely tight tolerances and has the highest quality surface finish. Our ultra-finished products have a roundness of 0.000025 inches and a standard UF size range of 0.0003 to 0.004 inches. Hard metals will typically result in the smoothest finishes, but the ultra-finish process is available for virtually any metal or alloy.

Applications

Our fine wires are ideal for use in a wide variety of industries and applications. These include the following.

Aerospace

Fine wires play a central role in the electronics and avionics utilized within the aerospace industry. Specific applications for these wires include navigation and communication systems, as well as GPS, communication satellites, and deep-space probes. This type of critical equipment requires the use of high quality, dependable wires that meet incredibly tight tolerances.

Electronics

From consumer electronics to photoelectric sensors, wires are integral to the electronics industry. Bonding wires, resistance wires, tin-plated wires, and stranded wires are all found in this industry in applications such as cell phones, semiconductors, lasers, and microwave components.

Medical

A few of the most common wire types found in the medical industry are:

- Staple

- Core

- Flat

- Braiding

- Round

These wires are utilized in a wide array of medical devices, including pacemakers, catheters, and biofeedback implants.

Research & Prototyping

During the research and development phases of a project, researchers want to partner with suppliers that can provide flexibility and high quality products. We work closely with our customers, offering confidentiality and fully-customized processes. We fulfill both small and large orders, and can produce prototypes in a timely manner.

Temperature Measurement TC Wire

Fine wires are often used for temperature measurement. Thermocouple (TC) devices utilize wires made of two different metals that will change voltage when heated or cooled. Resistance Temperature Detectors (RTDs) are another application of fine wires, offering higher levels of accuracy than thermocouples. RTDs contain a wire made from a single element, often platinum, copper, or nickel. As these materials change temperature, their resistance will change in a predictable manner that makes it possible to identify the temperature.

Read more » What is Thermocouple Wire?

Semiconductor Bonding Wire

Upwards of 40 billion integrated circuits are produced each year, each of which contains precision binding wire. We often utilize gold or aluminum for these products.

Resistance Wire

Resistance wire can be found in a wide array of industries, from automotive to medical. Applications for this wire include heating elements, neuroprobes, bathythermograph equipment, and speed sensors. This type of wire is commonly composed of copper, platinum, or nickel; however, other metals and alloys are also available.

Precious Metals Fine Wire

Available in a range of metals, including gold, platinum, and silver, precious metal wires are commonly used within pacemakers, cochlear implants, and many other applications within the medical industry. They are also found in aerospace and semiconductor applications. Coated, flat, and stranded wires are available with precious metal coatings.

Fine Wires from California Fine Wire Co.

Although precision is always important, there are many critical applications where accuracy and tight tolerances are simply non-negotiable. At California Fine Wire Company, our decades of experience enable us to offer products and services that are consistent, reliable, and of the highest caliber.

California Fine Wire Co.’s quality management system is ISO 9001 certified, and is equipped to perform the majority of physical, chemical, metallographic, and electrical testing on-site. Regardless of your project’s specifications, our team will work with you to create a custom order that meets your needs perfectly.

Request your quote today to begin working with us on your next fine wire project.